Page 18 of 38

Posted: Sun Jun 08, 2014 6:25 pm

by Brad1380

Well not a lot of progress on the Tiger due to the building project, but i have reached a milestone with that now so hope to pick up again on the restoration soon.

Done these so long agao now i've forgotten where they fit.

Not a good idea pulling the torch out of the welder when its running, fixed it eventually & fitted a euro torch conversion.

Ebay bargain scatter sheild, post shot blasting.

Took the hood frame apart, i thought matching the grey would be a problem, but once the vinyl was off the colour was much lighter, match was just standard light grey.

The flywheel is very rippled & with some cracking....

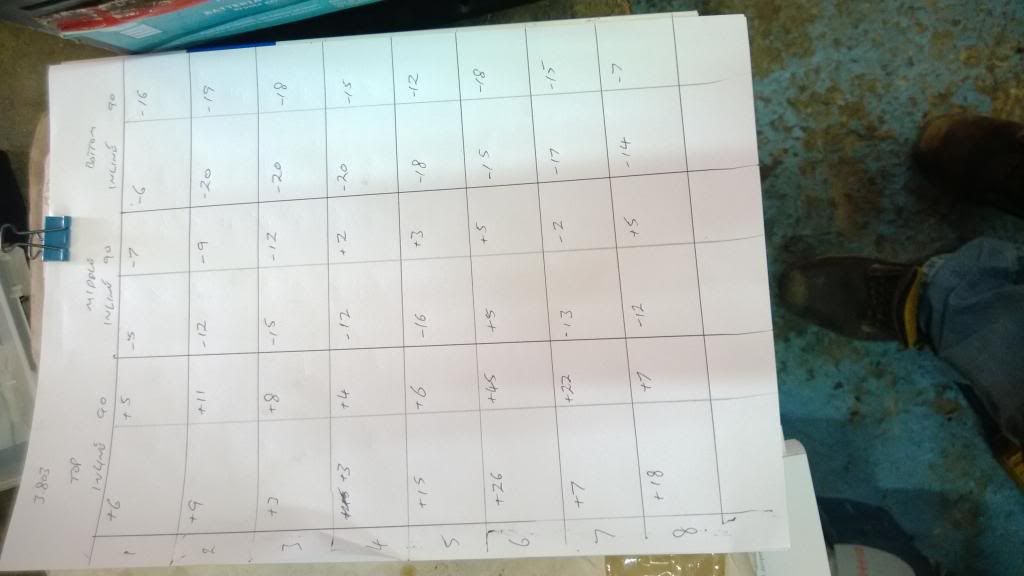

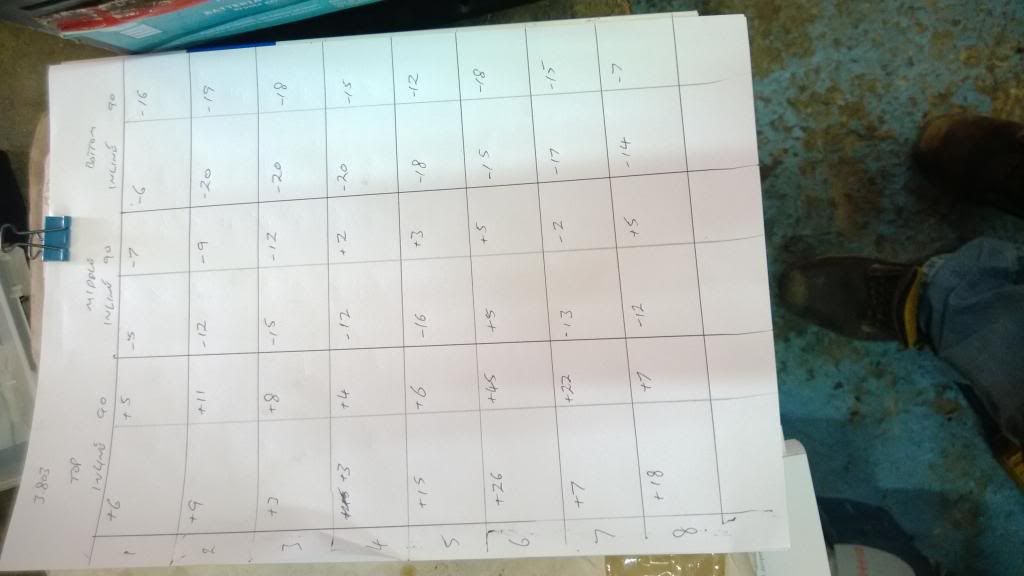

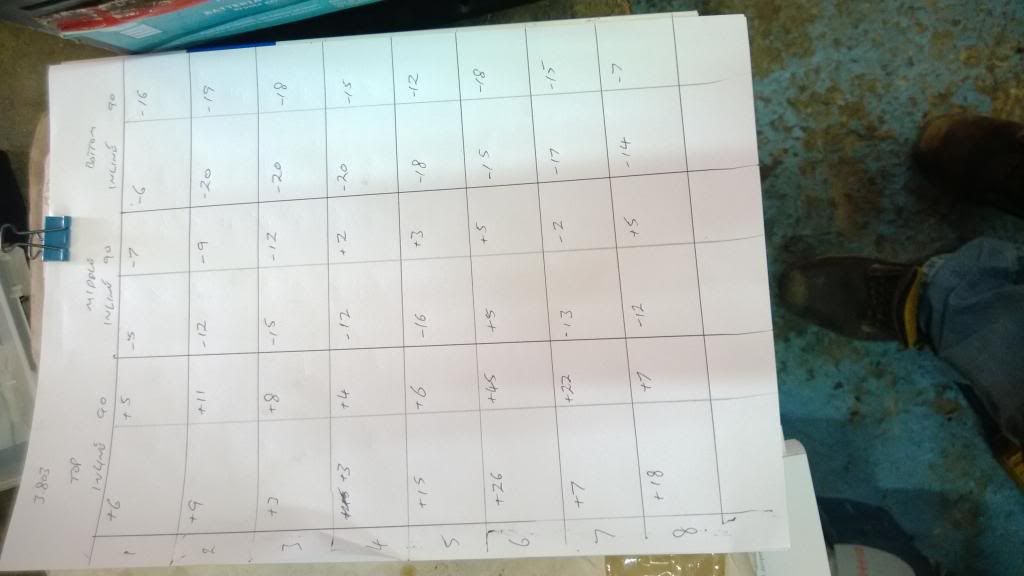

Tank dipped the block, then ran a Mercer bore gauge after a light hone to tidy the cylinders up.

I set the gauage at 3.803 as per the manual, i was getting readings less than this, i.e smaller diameter, but even with that the block looks well worn, with no.6 piston especially going wander about, thats a difference of 65 thou top to bottom.

Oh well i guess it opens up a whole new world of engine choices i suppose.

Brads Tiger

Posted: Sun Jun 08, 2014 11:21 pm

by redbaron

Brad,

the bellhousing that you have is not a Scatter Shield,but a cast iron 302/351 truck bellhousing.Dual bolt pattern transmission.

This iron bellhousing will shatter if the flywheel disintegrates,a true scatter shield is made from ballistic steel.

Lakewood are a reputable company for such,although fitting into a Tiger is tight due to the drawn depth of the B/Hsg.

Shelby American did make some Hi Nodular iron B/Hsgs in the sixties,yours is from the seventies.

Bit to heavy for a sports car.

Posted: Mon Jun 09, 2014 7:35 am

by Brad1380

It is heavy!, oh well i'll sell it on again.

Posted: Wed Jun 11, 2014 5:19 pm

by Brad1380

Been looking at a RS engine from Realsteel, not that expensive really when you start to tally up the parts & machining.

http://www.realsteel.co.uk/section2a.pdf

is there anything i should swap over or be aware of? any help would be appriciated as i'm new to V8's.

Posted: Thu Jun 12, 2014 9:11 pm

by pushrod

The RS motors are good value.

As a comparison I spent more in parts and machining costs on my 260, that's without any labour.

If I hadn't wanted to stay with a 260 I'd have gone for one of the RS 302's in a heartbeat.

Lou.

Posted: Fri Jun 13, 2014 4:46 pm

by Brad1380

Does anyone know if the head ports on the RS motor are the same as standard? so i don't have to fabricate new exhaust manifolds like Mal did.

Posted: Sat Jun 14, 2014 11:24 pm

by meadowhog

Those panels look like the inside covers of the soft top frame. They fit to the vertical hinged part when roof is up.

Posted: Mon Jun 16, 2014 9:24 am

by Mal

Brad1380 wrote:Does anyone know if the head ports on the RS motor are the same as standard? so i don't have to fabricate new exhaust manifolds like Mal did.

My heads were GT40P heads which are from Ford. Pretty sure they are the only head made by Ford with different a plug angle which causes the problem. As for aftermarket heads I don't know.

Posted: Mon Jun 16, 2014 3:57 pm

by Brad1380

meadowhog wrote:Those panels look like the inside covers of the soft top frame. They fit to the vertical hinged part when roof is up.

Thanks, i guessed they were part of the hood from the colour but i never took a photo of them in place.

Posted: Mon Jun 16, 2014 4:03 pm

by Brad1380

Mal wrote:Brad1380 wrote:Does anyone know if the head ports on the RS motor are the same as standard? so i don't have to fabricate new exhaust manifolds like Mal did.

My heads were GT40P heads which are from Ford. Pretty sure they are the only head made by Ford with different a plug angle which causes the problem. As for aftermarket heads I don't know.

I know the GT40 heads are the best, thats why you have them ). I need to have a long chat with RealSteel, but first i need a solid body, hopefully get onto that again now as i'm fed up building....

Posted: Mon Jun 16, 2014 7:44 pm

by Mal

Brad1380 wrote:Mal wrote:Brad1380 wrote:Does anyone know if the head ports on the RS motor are the same as standard? so i don't have to fabricate new exhaust manifolds like Mal did.

My heads were GT40P heads which are from Ford. Pretty sure they are the only head made by Ford with different a plug angle which causes the problem. As for aftermarket heads I don't know.

I know the GT40 heads are the best, thats why you have them ). I need to have a long chat with RealSteel, but first i need a solid body, hopefully get onto that again now as i'm fed up building....

Brad my heads are GT40P heads not GT40. tHE GT40 HEADS have the same spark plug angle as the 260-289 302 heads.

Is that another restoration project ?. Do you have a before pic.

Posted: Tue Jun 17, 2014 6:41 pm

by Brad1380

Mal, thats probably the best photo, before it was rather dark in there, i can tell you that as it was an old cow shed the floor was on a slope for all the cow urine to flow out, i had to take 120 tonnes out of there to get the new floor base right. You can see the old floor marks on the walls.

Posted: Tue Jul 15, 2014 9:47 pm

by Brad1380

This was rather bent up before, flattened it out & sorted out the broken latch.

First test of the repaired welder as the sprung pistons had come away from the aduster.

Posted: Sun Jul 20, 2014 6:35 pm

by Brad1380

Got this far with the Brembo disc spacers before the F1 race, will finish then off when the fasteners arrive.

Posted: Tue Jul 22, 2014 5:41 pm

by Brad1380

The repair panel for the OS front part of the rear wheel arch was a bit out.

Had to let in a 3/16 slither to get it looking right, need to make up the inner wing section next.

The welder is going better now with a proper torch conversion.